Designed by engineers, for engineers.

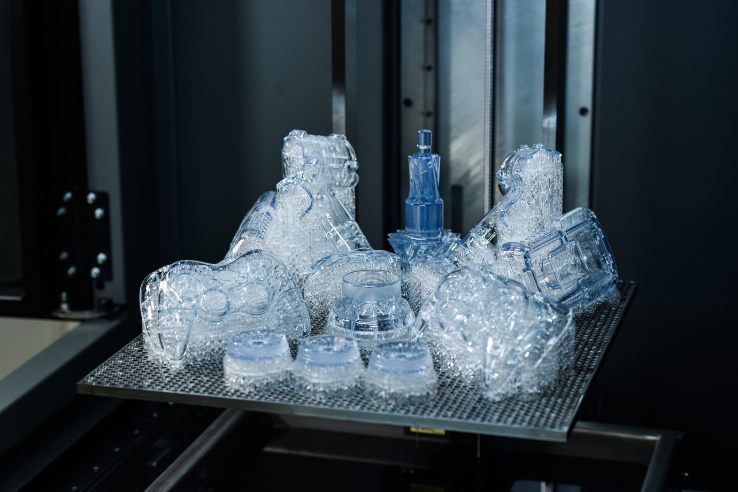

Achieve superior part quality with the Neo series, designed for high-accuracy stereolithography (SLA) printing. Neo 3D printers build precise, repeatable parts with smooth finishes, minimizing post-processing and accelerating workflows. From large-format production to detailed prototyping, they handle demanding projects with ease. Built for reliability, Neo printers excel in tooling, master patterns, and production parts. Trusted by F1, automotive, and consumer industries, they help teams cut lead times and produce high-quality parts with confidence.

Key Benefits

Optimized speed and precision for the Neo800+ 3D Printer

If you’re looking for higher throughput, the Neo800+ 3D printer can achieve up to 50% faster builds than with the Neo800 printer, thanks to ScanControl+.

ScanControl+ enhances border control, resulting in sharper corners, smoother edges, and finer details. It optimizes laser pathing to ensure faster, more efficient scanning, while intelligent energy delivery maintains part fidelity even at higher speeds.

Versatile SLA materials for every application

Designed with an open resin system, Neo printers such as the Neo450s, Neo800, and Neo800+ 3D printers are designed to run the most technically advanced SLA materials, including the Somos® resins range.

From clear, tough and durable resins to high-temp rigid options, the combination of Somos SLA resins and Neo 3D printers deliver superior accuracy, durability, and surface quality for prototypes and production parts. Somos resins are available for standard use to run on the Neo800 3D printer and Neo450s 3D printer. The Neo800+ 3D printer further expands capabilities by supporting both standard and ScanControl+ ready materials for faster build speeds.

Explore how stereolithography 3D printing with the Neo 3D printer is empowering industries to build the future of manufacturing and design.

Compare model sizes and material capacities to see which one is right for you.

Industries ranging from F1 through to service bureau have already invested in the Neo® SLA 3D printer for rapid tooling, prototyping and casting master patterns. Find out more about how the Neo 3D printer is making an impact in innovation and product development.

GrabCAD Print™ for Neo® delivers a seamless, cost-effective, and easy-to-use platform for essential stereolithography (SLA) build preparation, centralizing the management of Stratasys' entire 3D printing ecosystem in one powerful solution.

Titanium is an easy-to-use software interface available on Neo SLA 3D printers. Titanium software allows users to start builds quickly and monitor throughout the building process. Software updates are driven by customer suggestions and feedback, providing a system that is optimized for customers and their applications.

A range of Neo® accessories are available to support your SLA 3D printing workflow.

Conveniently pick up and unload the Neo800® platform and parts up to 40kg in weight with the Neo® Unload Trolley. The integrated drip tray prevents resin contamination of machine and surrounding area. The Neo® Unload Trolley easily and safely supports your 3D printing workflow.

Printed parts need to undergo a final post-cure process. The UV800 is designed to fulfill this requirement with high-intensity UV lamps and turntable. Exposure processing times are controlled via a dedicated PLC with an HMI screen.

The lower half of the UV800 is a heated resin store, maintaining resin at VAT temperature. This avoids any significant temperature changes when refilling a vat.

Faster, safer resin removal for the Neo Series.

We recommend the DEMI 4100 or DEMI 830 by PostProcess® for fast, efficient resin removal from Neo-built parts. Both systems eliminate manual cleaning, reduce waste, and process large builds in 10 minutes or less. Using non-flammable, low-waste detergents, they enhance safety and sustainability while delivering consistent, high-quality results.

Less handling, less downtime. Just clean, ready-to-use parts.

Reach out to your local representative for more details on how the PostProcess Technologies fits into your production workflow.