Explore how stereolithography 3D printing and the Neo® is helping industries build the future of manufacturing and design.

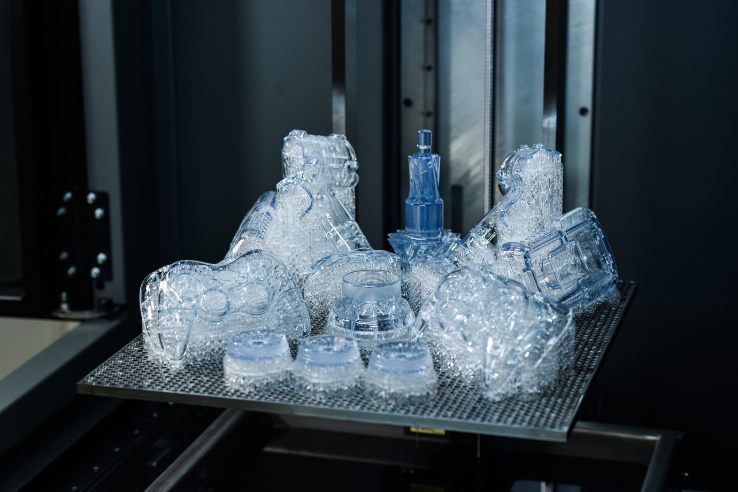

The reliable and proven Neo series of 3D printers build high-quality parts with superior surface quality, accuracy and detail.

Industries ranging from F1 through to service bureau have already invested in the Neo® SLA 3D printer for rapid tooling, prototyping and casting master patterns. Find out more about how the Neo is making an impact in innovation and product development.

GrabCAD Print™ for Neo® delivers a seamless, cost-effective, and easy-to-use platform for essential stereolithography (SLA) build preparation, centralizing the management of Stratasys' entire 3D printing ecosystem in one powerful solution.

A range of Neo® accessories are available to support your SLA 3D printing workflow.

Conveniently pick up and unload the Neo800® platform and parts up to 40kg in weight with the Neo® Unload Trolley. The integrated drip tray prevents resin contamination of machine and surrounding area. The Neo® Unload Trolley easily and safely supports your 3D printing workflow.

Titanium is an easy-to-use software interface available on Neo SLA 3D printers. Titanium software allows users to start builds quickly and monitor throughout the building process. Software updates are driven by customer suggestions and feedback, providing a system that is optimized for customers and their applications.

Printed parts need to undergo a final post-cure process. The UV800 is designed to fulfill this requirement with high-intensity UV lamps and turntable. Exposure processing times are controlled via a dedicated PLC with an HMI screen.

The lower half of the UV800 is a heated resin store, maintaining resin at VAT temperature. This avoids any significant temperature changes when refilling a vat.