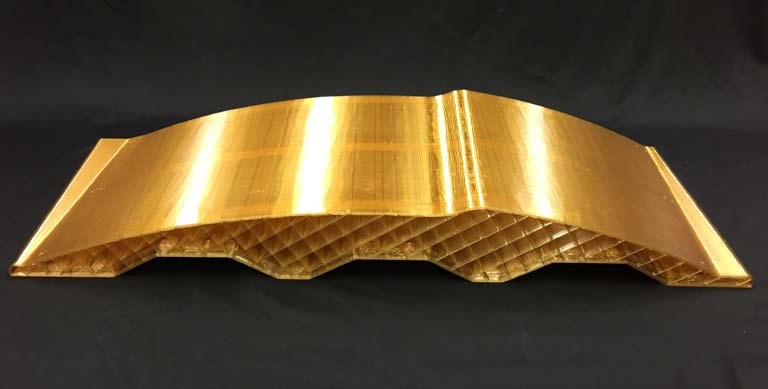

3D print cost-effective, high-temperature, custom tools in days — instead of the weeks or months required for traditional tooling processes. Whether your application requires reusable layup mold tooling or sacrificial tooling for complex, trapped-tool geometries, FDM simplifies the fabrication of composite parts while providing unparalleled design freedom.

Build tools in days versus weeks or months for traditional tooling with more than 90% cost savings.

Tool designs specifically tailored to your application versus the “one size fits all” approach.

Transition from pre-production parts to production in days with a digital inventory of tool designs ready for build.

Build tools in days versus weeks or months for traditional tooling with more than 90% cost savings.

Tool designs specifically tailored to your application versus the “one size fits all” approach.

Transition from pre-production parts to production in days with a digital inventory of tool designs ready for build.