Save time, reduce cost and improve safety by making jigs, fixtures and other manufacturing tools with 3D printing.

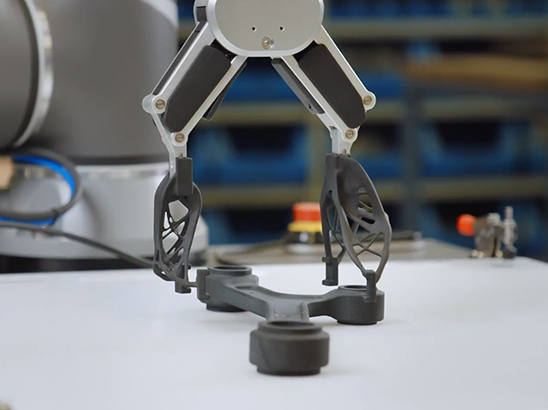

3D printing offers a much more efficient way to create jigs and fixtures, assembly and inspection aids, end-of-arm tooling, soft jaws, and forming dies. That’s because these tools can be printed in hours vs. days or weeks it takes with traditional fabrication methods. Jigs and fixtures manufacturing with strong thermoplastics offers a lighter alternative to metal, and 3D printing’s design freedom allows for optimal ergonomics and user-friendly tool designs.

3D printing is transforming how manufacturers create jigs and fixtures, providing a flexible, cost-effective alternative to traditional machining. Learn how 3D printing eliminates inefficiencies, speeds up manufacturing, and reduces material waste while improving worker ergonomics and safety.

Transform anyone on your team into a fixture designer. The fixturemate integration, powered by trinckle eliminates the CAD barrier with an intuitive workflow that takes you from workpiece upload to print-ready fixture in minutes—no design experience required.

Key Benefits:

Stop waiting weeks for custom tooling. Your operators and engineers can now create exactly what they need, when they need it.

3D printed jigs and fixtures offer benefits across multiple industries.

Aerospace companies leverage 3D printed drill guides, ground support equipment and other tools to meet schedules and cut costs.

3D printing allows faster, on-demand tool creation to minimize downtime and keep production lines operational.

Valiant TMS

The Valiant TMS AM Lab printed the tool on the Origin 3D printer, whose P3™ DLP technology offers an injection mold-like surface finish, and that comes with a broad range of specialty materials. This resulted in a 78% cost reduction and 79% faster print time compared to other additive processes.

Microsoft

3D printing plays an integral part in Microsoft's "Fail Fast" development process and PolyJet™ models are a part of our daily routine.

Parker Hannifin

When tooling engineer Dave Howe was asked by his manager what would help the company move forward, Howe’s reply was “additive manufacturing” (AM). What he probably didn’t realize at the time was that his vision for how AM technology might help would change how they do business, and they’d never look back.

Valiant TMS

The Valiant TMS AM Lab printed the tool on the Origin 3D printer, whose P3™ DLP technology offers an injection mold-like surface finish, and that comes with a broad range of specialty materials. This resulted in a 78% cost reduction and 79% faster print time compared to other additive processes.

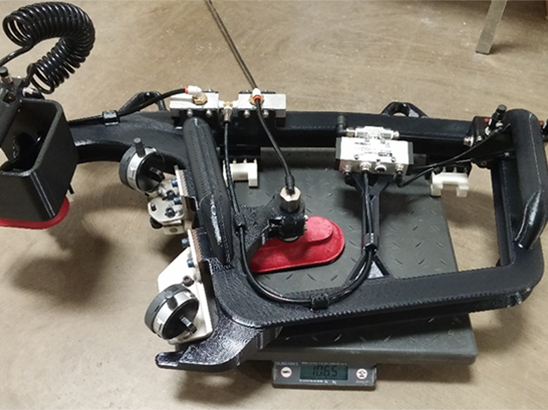

Parker Hannifin

When tooling engineer Dave Howe was asked by his manager what would help the company move forward, Howe’s reply was “additive manufacturing” (AM). What he probably didn’t realize at the time was that his vision for how AM technology might help would change how they do business, and they’d never look back.