The design freedom and tool-less nature of 3D printing means composite lay-up tools can be printed in hours or days, regardless of geometry. They are lightweight and, depending on the material used, can withstand autoclave cure. Compare this to heavy conventional tooling that can take months to procure.

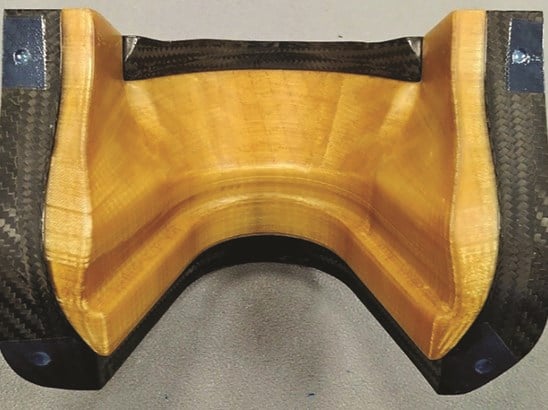

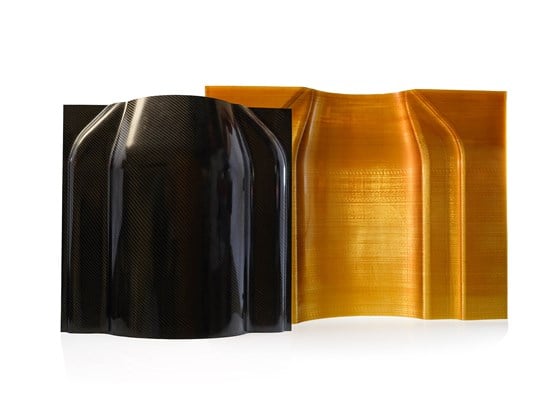

Soluble sacrificial tooling simplifies the production of hollow composite parts, avoiding trapped tool scenarios. Once the composite is cured, the 3D printed tool is dissolved, enabling one-piece, seamless structures.

Large capacity and high-performance materials make the F900 highly suitable for composite tooling.

The Fortus 450mc offers similar print capabilities as the F900, but with a smaller footprint and build volume.

Large capacity and high-performance materials make the F900 highly suitable for composite tooling.

The Fortus 450mc offers similar print capabilities as the F900, but with a smaller footprint and build volume.

Simple but robust design, open materials and high reliability and uptime define Neo SL printers.

In this design guide you’ll learn the best practices for the design and fabrication of 3D printed composite tools, and see how various customers have achieved success with this technology.

3D printed composite tooling offers benefits for virtually any industry that produces composite structures.

Printed composite tools let aerospace companies iterate designs quickly while minimizing cost and schedule impact.

Tooling solutions like 3D printed composite molds help automakers increase efficiency by taking time out of the manufacturing process.

Printed composite tools let aerospace companies iterate designs quickly while minimizing cost and schedule impact.

Tooling solutions like 3D printed composite molds help automakers increase efficiency by taking time out of the manufacturing process.

Additive manufacturing offers many consumer product applications, including tooling for composite structures.

Javier García, Director of Wehl & Partner

Customer Success StoryComposite tooling solutions let SSL respond to design changes with unprecedented speed while lowering cost.

Silverstone Composites and Mackart Additive turned to 3D printed sacrificial mandrels to make lay-up tools for composite pipes.

Compositex eliminates costly outsourcing and reduces production lead times using 3D printed composite tools.

Dassault bypassed the traditional composite tooling route and opted for 3D printing, achieving significant time and cost savings.