Custom parts and small-batch production runs that otherwise would be uneconomical to make with traditional machining or moulding become possible with F123 Series printers. Durable materials and soluble support offer unlimited design freedom.

Materials specifically tailored for creating 3D printed jigs, fixtures and manufacturing aids can make your production floor more efficient and your tooling more ergonomic and worker-friendly.

Easy-to-use F123 Series printers let you iterate your designs much more quickly than traditional prototyping methods. The quiet operation and compact size make the printer suitable for the office or the factory floor.

F123 Series systems are the perfect 3D printers for schools. Easy operation and built-in safety features make them a great tool for teaching students highly desirable skills needed in manufacturing, design and engineering careers.

Discover how 3D printing, also known as additive manufacturing (AM), can revolutionize your factory floor operation. AM tools can increase production, elevate quality, lower costs, and reduce worker injuries, benefiting all areas of the manufacturing process.

Compared to conventional tool-making methods, 3D printing offers significant cost savings, reduced lead time, and the ability to iterate tool design much more efficiently.

Download our solution guide to explore the benefits of adopting AM tooling and learn how it can optimize your production processes and improve efficiency. Don't wait - unlock the power of AM tooling today!

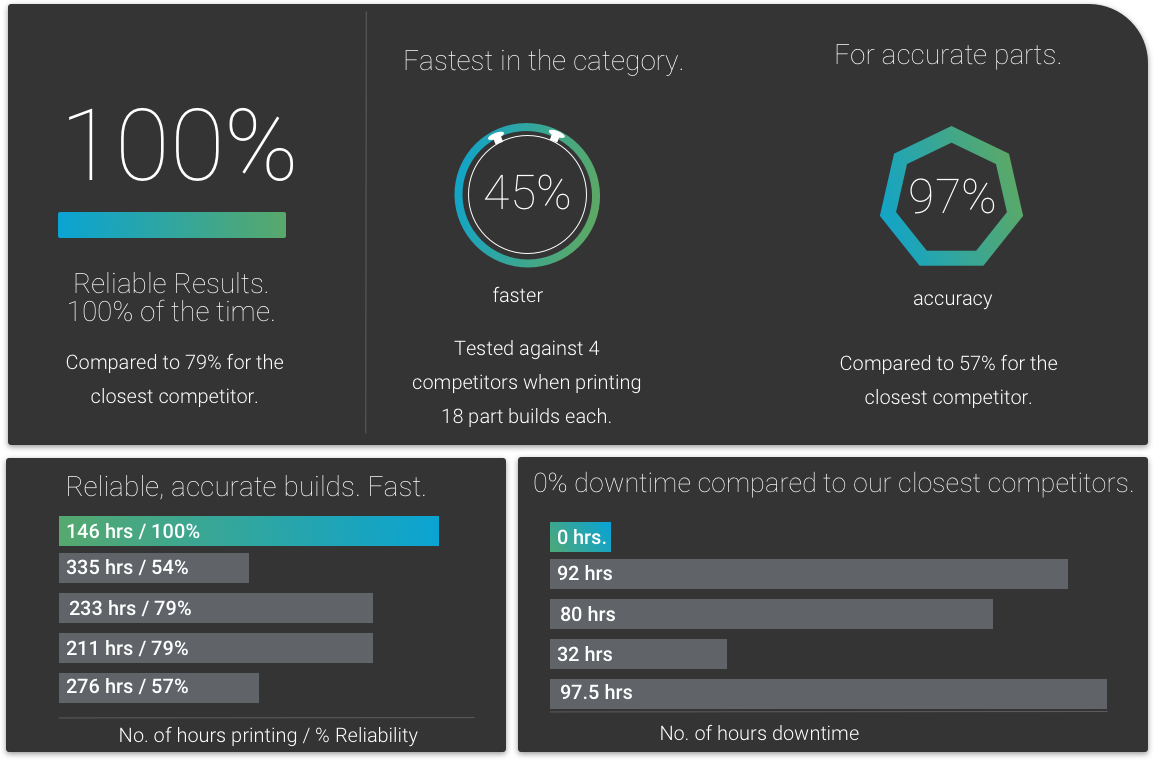

Printer performance and reliability have a direct impact on your bottom line. Stratasys' F123 line of FDM 3D printers is not only the most accurate compared to various competitors, it is also the fastest, with the least down time. Confidently print more parts in less time with a Stratasys F123 series FDM 3D printer.

Download our head-to-head study to see how F123 printers fare against the competition.

Desktop and low-priced 3D printers may seem like the logical choice to get started with 3D printing. But it’s often the wrong choice because these kinds of 3D printers are typically not up to the task nor have the trusted reliablity of FDM technology.

This white paper highlights a third-party head-to-head comparison and how each 3D printer fared. Curious to know how F123 Series FDM 3D printers stack up against these compeitors?

Download this white paper, evaluate and learn how F123 Series out preforms it's competition.

With two to choose from, there’s an F123 Series printer that’s right for your application, from manufacturing to education.

There’s virtually no limit to the ways you can put F123 Series printers to work. Get a taste of how you can benefit by viewing some of the applications and parts other F123 users have implemented. Through clear, colourful images and descriptions, this Look Book will show you how versatile these printers can be.

Download lookbookPolaris has a rich history developing powersports vehicles like motorcycles and ATVs to tactical vehicles for government and defense. The company relies on innovative technologies to solve everyday problems on the manufacturing floor. Of those assets used to provide a variety of solutions, you'll find Stratasys FDM 3D printers such as, F123 Series 3D printer.

"The biggest benefit of partnering with Stratasys. Is the ability to iterate on new tooling designs. Being able to come up with a design, test it, improve apon it, and repeat till we come up with a great product. We install a lot of complex parts badging, head dresses, things of that nature to our bikes. Having the ability to 3D print that complex geometry quickly and in a variety of materials gives us a lot of flexability." - Dan Wiatroski

See how Polaris advanced their manufacturing by integrating F123 Series 3D printers. You'll also witness the wide range of materials avaliable to choose from. Further opening more doors to iterate on new tooling designs, giving them the flexibility needed to meet ever-changing production needs.

Most companies still rely on slower, costlier ways of making manufacturing tools. But the ones that have switched to 3D printing where it’s appropriate see tangible benefits in lead time, cost, functionality and ergonomics.

Dive into one of the best kept secrets in manufacturing. Our virtual factory floor to learn where and when 3D printing offers a good fit for jigs, fixtures, production parts, tooling, and other manufacturing aids for better factory-floor operations.

Staying competitive means getting your products in the marketplace faster than your competition. And that means prototyping faster and more effectively to vet your ideas and optimise your product. The In this white paper, we’ll show you how the F123 Series printers let you rapid prototype smarter and faster, so you’re more productive and your products are ready for market.