During a visit with Christian Saurman, the CEO and co-owner of NEO Lab, a family-owned digital orthodontic lab in Andover, Massachusetts, the Stratasys team wanted to learn how our technologies could make the day-to-day easier for their 120 employees who work with about 3,000 orthodontic and pediatric dental clinics around the country.

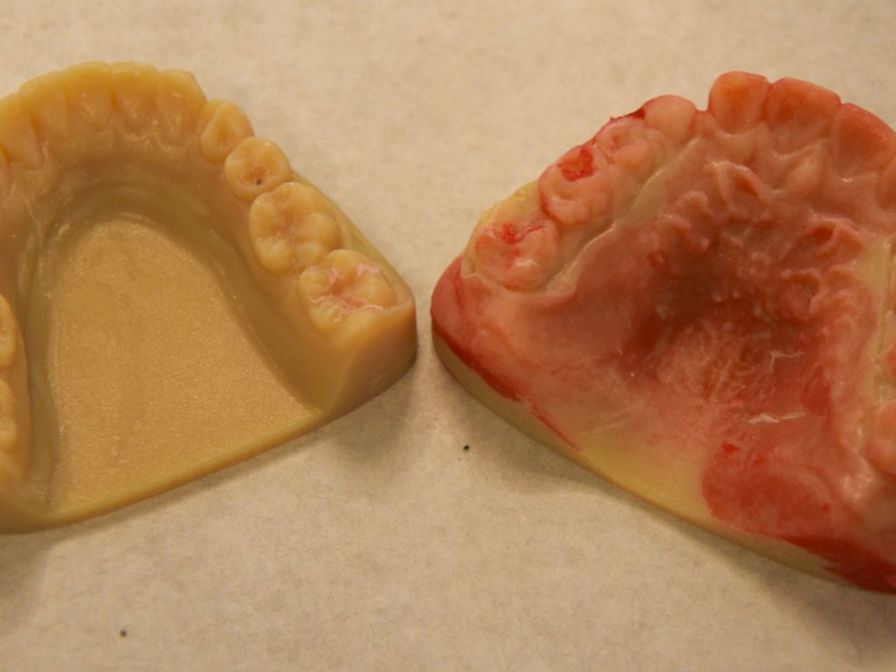

Saurman explained how time-consuming and messy it is to create acrylic devices using a traditional separator liquid because it requires careful application, more product and it tends to bleed around the model. It also takes longer to dry and because it’s hard to remove the appliance from the model, the model can easily crack. He liked how the support layers printed on PolyJet act like a natural separation to release the acrylic. And if Stratasys could figure out a way to infuse more of the separator into the final layers to make the device easily pop off it would be a game changer.

This discussion evolved into the development of the Stratasys Separator Digital Materials (DM). Separator DM infuses with the model resin, easing the separation of the acrylic device from the model — making the removal of wax and acrylic residues easy — resulting in better surface quality and decreased manual labor.

This game-changing feature was developed in partnership with Saurman and his team, which included fine-tuning the amount of support and model material needed to release the acrylic in order to achieve a better finish underneath the appliance.

“During production, we’re taking printed resin models and marrying them with acrylic resin. These two will bond, and then we’ve created one big piece of resin that isn’t coming apart,” says Saurman. “This is the reason we use Stratasys 3D printers for our acrylic work — the layers of support material provide a separation for the two resins that just isn’t naturally available in DLP or SLA printing.”

Now that Separator DM has been tested and perfected, Saurman says the impact of using it has been “huge” for NEO Lab. The initial reason he wanted to work on this project with Stratasys was to get a better finish on their appliances: “Ultimately, we want a better product that is going out to the offices.” But in doing so they found that there were so many other advantages that came out across the board using Separator DM, such as decreased manual labor, increased accuracy and a better experience for the customer.

When using separator DM, Saurman says the only parts that need to be rinsed are the undercuts of teeth and the pedestal, the bottom of the model that sits on the print tray. At NEO Lab, they just use a putty knife to scrape off the support on the bottom and it is postprocessed and ready to hit the floor. Whereas before, the model would be completely encased in support and they would have to waterjet it off or put it in the tumbler and tumble off the support.

“We didn’t even know that was going to happen with the Separator DM,” says Saurman. “And we were super excited about it because before we had one fulltime and one part-time employee working 15 hours a day water jetting all the models. Now we are able to shift their workload to something else.”

Saurman says Separator DM saves NEO Lab about three minutes per model. And half of that time-savings is postprocessing, the other half is not having to apply the separator. Before using Separator DM, their acrylic department used to struggle to free the device from the model. Now instead of spending 30 seconds per model it takes NEO Lab five seconds, which really adds up when they are making 550 – 600 appliances a day.

In addition to saving time, the easy separation also helps NEO to increase accuracy. For example, a tech would struggle when prying the acrylic up on a retainer using standard separator. And the wires might have flared up, which would then need to be bent back to the original shape. But with Separator DM, the acrylic easily pops off the model, so the wires stay in place leaving the device highly accurate.

In addition to the better surface quality that comes with using Separator DM, the 3D printed models also end up looking really polished, so the dentists NEO Lab works with are giving them to their patients. They even have dentists that present the 3D printed model and appliance in a finished box with their logo as a parting gift.

“The experience is what we are trying to enhance. When I was selling the digital experience, we always talked about the last impression,” says Saurman. “You’re going to remember the last impression of the office and you’re going to remember how they treated you on the way out the door.”