3D printing, also known as additive manufacturing, breaks from traditional manufacturing with more efficiency, flexibility, and greater sustainability.

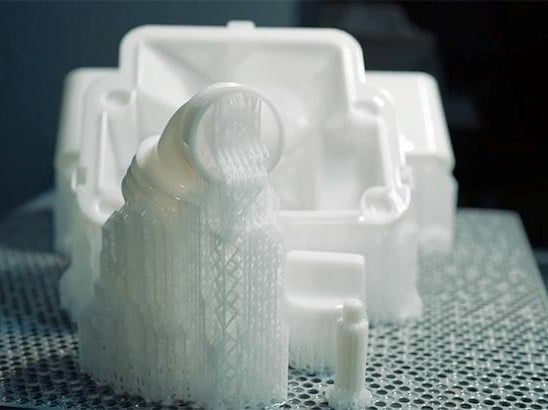

3D printing, an integral part of industry 4.0, overcomes the constraints of traditional machining, molding, and joining technologies.. This technique, which adds rather than subtracts material and requires no support tooling, boosts efficiency and minimizes waste. It fosters quicker production of optimized manufacturing tools and allows assemblies traditionally needing bolting or welding to be printed in one piece. At its core, 3D printing in manufacturing enables significant time and cost efficiencies while enhancing design flexibility.

3D printing’s fast, on-demand parts manufacturing capability offers an opportunity to better manage the supply chain.

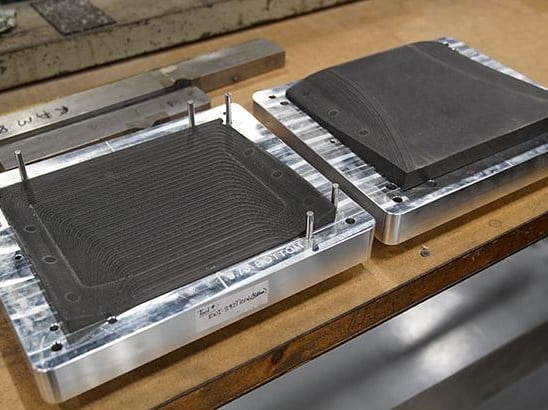

This Solution Brief describes the benefits of manufacturing automotive end-use parts with SAF 3D printing technology, resulting in more control over production and lower cost than injection molding.

Virtually any industry involved in the manufacture of goods can benefit from 3D printing.

From light but strong airworthy parts to specialty materials for space flight, 3D printing gives aerospace manufacturers more options.

Rapid prototype for mission-critical parts, reduce logistics and supply chain risks, and establish on-demand readiness.

View more3D printing gives automakers more agile tooling options, economical on-demand part production and better supply chain solutions.

Rapid prototype for mission-critical parts, reduce logistics and supply chain risks, and establish on-demand readiness.

View moreStefan Kammann, Continental Engineering Services

Customer Success StoryManufacturing 3D printing (also known as industrial additive manufacturing) enables fast, digital production of custom parts, tools, and components. It streamlines workflows by reducing setup times, minimizing manual labor, and enabling design iteration without retooling.

3D printing supports low- to mid-volume production of final parts directly from CAD. It eliminates tooling delays, shortens lead times, and enables customization without added cost or complexity.

Additive manufacturing reduces tooling costs, accelerates time to market, and improves uptime by enabling rapid repair or replacement of factory equipment. It also mitigates supply chain disruptions by enabling localized, digital part production.

Stratasys offers a broad range of production-grade thermoplastics (e.g. ABS, ULTEM™, Nylon), elastomers, and resins designed for strength, heat resistance, and repeatability. Specialty materials support ESD safety, biocompatibility, and high durability.

Custom tools, brackets, replacement components, and many other parts can be printed in hours, not weeks. This helps reduce unplanned downtime and enables rapid response to design or production changes.

Start by identifying high-cost, slow-turnaround, or low-volume parts in your operation. Then consult with a Stratasys expert to assess the right technology, material, and implementation strategy for your needs.

For a company passionate about continuous innovation, SAF 3D printing technology lets DQDB bring life to a creative design.

General Atomics has fully embraced 3D printing, making the most of this technology to innovate and stay competitive within aerospace.

Peugeot designers capitalized on PolyJet textile printing technology for interior components of its Inception Concept vehicle.

3D printing, also referred to as Additive Manufacturing, is often viewed as a manufacturing process competing — or at least trying to compete — with the more well-established injection molding process for the production of plastic parts.

View more3D printing, also referred to as Additive Manufacturing, is often viewed as a manufacturing process competing — or at least trying to compete — with the more well-established injection molding process for the production of plastic parts.

View more