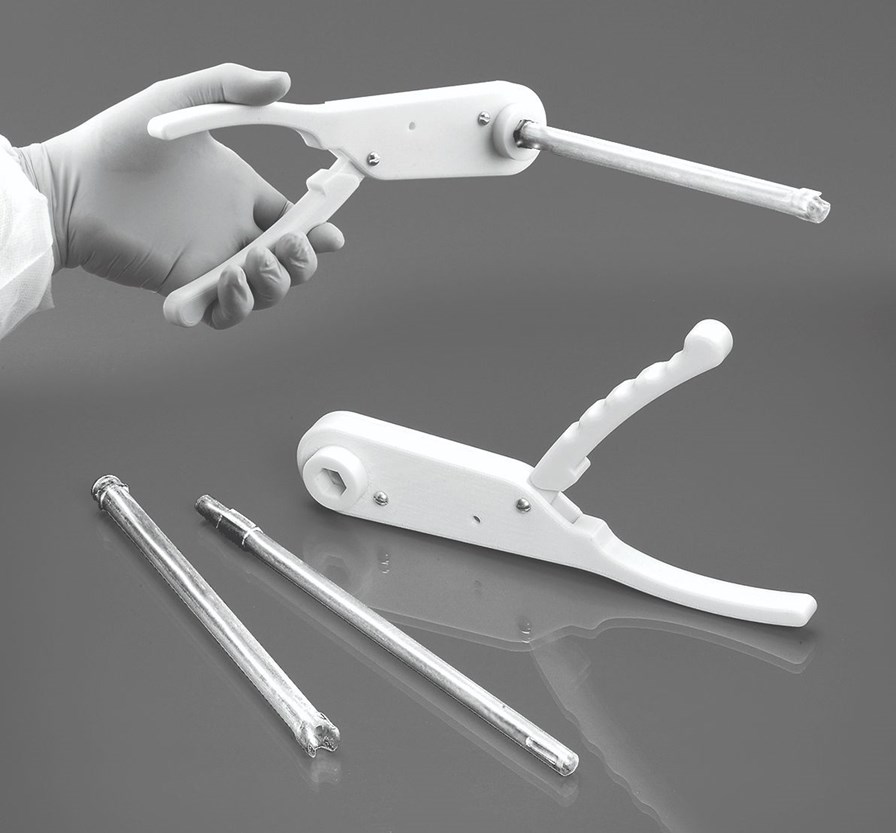

Sofamor Danek engineers recently designed a ratcheting counter-torque instrument that surgeons use to fasten set-screws to a corrective implant on a patient’s vertebrae. After the screws are fixed in place, the tool shears off the screw heads at a pre-set torque level. The existing method required surgeons to use separate tools, working them in opposing directions, using both hands. The result was often a violent impulse that occurred at the moment the screw head sheared off, and the surgeons wanted to eliminate that.

The financial advantages of including FDM technology in the prototype lab are evident to McDonald. “Now we can refine our designs more before we start cutting metal, which is where the dollars start going up exponentially. He sees savings mount as more prototypes are made inhouse. “We have several divisions and each one has its own dedicated engineering staff that comes to our RP lab with modeling requests. Except for display items, almost everything that comes off the FDM machine is for functional evaluation.

That saves the company a lot of money. The cost of sending out work versus doing it in-house is easy to capture and we can justify owning the [Fortus]FDM system via reducing that cost alone. But the intangibles like timing issues, communication, and the value-added services are where we see the greatest benefits.

“At Medtronic - Sofamor Danek, cutting-edge medical technology takes new shape, thanks in part to FDM prototyping technology,” says rapid prototyping designer, David Freeman. “Forward-looking companies seek forward-thinking partners.”

“The tool we developed combines the two existing tools into a single unit,” says design engineer Richard Franks. “As the surgeon squeezes two handle pieces together, the ratchet tightens the screws.” The engineers produced a working polycarbonate ratchet strong enough to withstand testing on stainless steel set-screws and durable enough to survive an autoclave. In addition, says senior engineering manager Troy McDonald, “Surgeons are really rough on these prototypes while trying them out, so we have got to have tough material.FDM gave us the strength and durability we needed.” Medical technologists advancing surgical techniques appreciate the impact of FDM technology, according to McDonald.

“FDM turned out to be an important tool for us,” he says. “The benefits of functional prototypes extend to communication too,” he says, “Being able to use the rapid prototypes has really cut down on miscommunication.” After sending the counter-torque ratchet out to three hospitals, Sofamor Danek learned that the tool design could be improved by rotating its handle 90 degrees — information it might not have learned without working prototypes.