Save time, reduce cost and improve safety by making jigs, fixtures and other manufacturing tools with 3D printing.

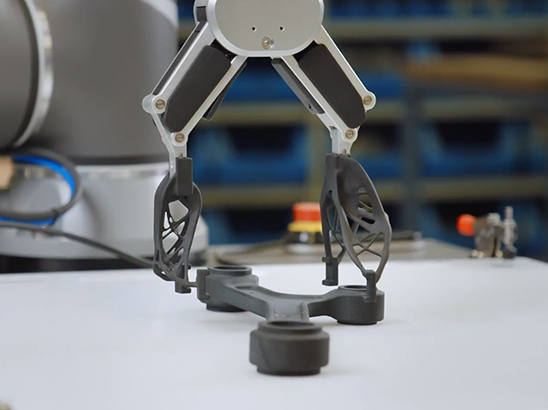

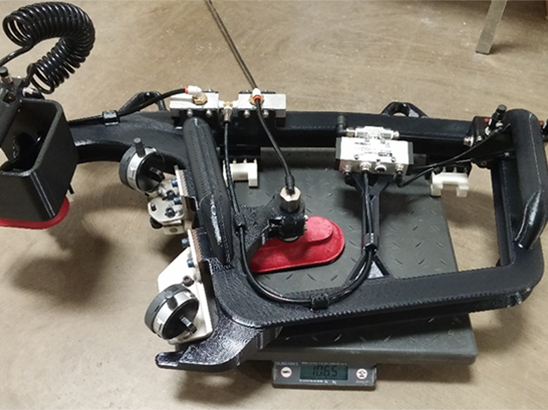

3D printing offers a much more efficient way to create jigs and fixtures, assembly and inspection aids, end-of-arm tooling, machining soft jaws and forming dies. That’s because these tools can be printed in hours vs. days or weeks it takes with traditional fabrication methods. Jigs and fixtures manufacturing with strong thermoplastics offers a lighter alternative to metal, and 3D printing’s design freedom allows for optimal ergonomics and user-friendly tool designs.

These 3D printers represent suitable systems for jigs, fixtures and other tooling applications.

The Fortus 450mc delivers industrial-grade printing with a highly versatile range of materials.

Large capacity and high-performance materials make the F900 suitable for many tooling applications.

H350 powder bed technology offers the most cost-effective way to print tools and parts at scale.

F3300 next-gen FDM technology offers up to 2X the print speed and throughput of legacy printers.

All manufacturing operations use jigs and fixtures in some form, but making them with outdated methods is costly and time consuming. As this guide shows, 3D printing offers a better alternative.

3D printed jigs and fixtures offer benefits across multiple industries.

Aerospace companies leverage 3D printed drill guides, ground support equipment and other tools to meet schedules and cut costs.

3D printing allows faster, on-demand tool creation to minimize downtime and keep production lines operational.

Aerospace companies leverage 3D printed drill guides, ground support equipment and other tools to meet schedules and cut costs.

3D printing allows faster, on-demand tool creation to minimize downtime and keep production lines operational.

3D printing’s limitless design capability lets doctors create patient-specific surgical guides for more effective outcomes.

Rachel Trimble, GKN Aerospace

Customer Success Story3D printed work holding devices reduce machine setup time by 80% while freeing up CNC capacity.

When a conveyor system needed repair, GM engineers turned to 3D printed replacement parts that reduced weight and cut lead time.

3D printed work holding devices reduce machine setup time by 80% while freeing up CNC capacity.

When a conveyor system needed repair, GM engineers turned to 3D printed replacement parts that reduced weight and cut lead time.

3D printing’s ability to easily tailor the design to the task makes it a perfect fit for customized jigs and fixtures.