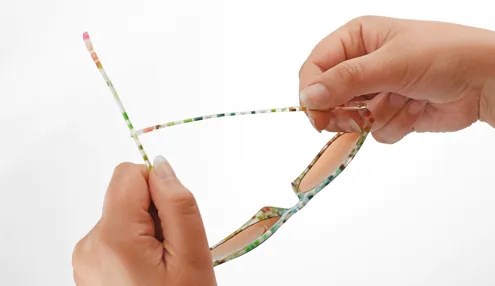

Turn eyewear designs into functional prototypes that accurately simulate the look, feel and function of frames in a range of colors and materials. Reduce product development times and answer every prototyping requirement, from final approval to drop tests, lens mounting and wear-ability tests, with VeroFlex. Create true-to-life prototypes fast to stay ahead of market trends and increase eyewear sales.

Experience the power of Stratasys 3D printing for medical devices like never before.

Learn MoreStratasys J735 and J750 that combine the realism and speed to get you where you need to be – faster.

Learn MoreThe power of digital materials starts at the Connex two and the capabillities go up with the Connex 3.

Learn More20-30 J/m

42-50°C

48-88 MPa

43-64 MPa

View various eyewear prototypes 3D printed in various color combinations of VeroFlex on the Stratasys J750.